class 100 clean room definition

A cleanroom is an environment where airborn particulates are controlled through an exchange of highly filtered air using a high efficiency particulate air HEPA filtering system and through minimization of activities that generate particles. Cleanroom for microelectronics manufacturing with fan filter units installed in the ceiling grid.

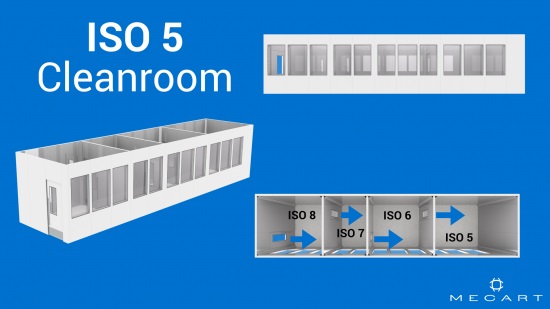

Clean Room Classifications Iso 8 Iso 7 Iso 6 Iso 5 Mecart

By comparison your typical office space has between 500000 and 1 million particles per cubic foot.

. To meet the same standard using the high-end air change recommendation 480hour requires 12 FFUs. The maximum allowable particles for particles for a Class 10 Cleanroom are below. Head cover goggles beard cover lab coat foot coverings or booties and gloves suitable to the task ie.

What is a class 100 cleanroom. Clean room has HEPA filters to clean the incoming area. In normal situations these conditions are provided by a laminar air flow workstation.

They look almost like astronaut suits but are not quite as heavy and dont require the large boots for. The room is under constant positive pressure. Six HEPA filters are installed in the ceiling above the Class 100 workspace.

Class 10000 This classification of clean room is the one mostly commonly used in the food industry and limits particles to 10000. Cleaning solvents can be Di Water a blend of Di Water and Isopropyl alcohol blends cleanroom compatible cleaners and. Class 10 Cleanroom is the second classification type of the FED-STD-209 classification standard the Class 10 Cleanroom corresponds to the Class 4 Cleanroom of the ISO standard.

350 per cubic foot. Cleanrooms are classified according to the number and size of particles permitted per volume of air. A class 100 cleanroom has 100 particles per cubic foot.

Class 100000 cleanrooms or ISO level 9 rooms also exist. A Class 100 clean room has no more than 100 particles. A class 100 cleanroom maintains less than one hundred particles larger than 05 microns in each cubic.

Large numbers like class 100 or class 1000 refer to FED_STD-209E and denote the number of particles of size 05 µm or larger permitted per cubic foot of air. If its breached air can only move outward never inward. Definition of the different Clean Room Classes Former FED STD 209 E - overview cancelled Class Name 01 micron 02 micron 03 micron 05 micron 5 micron 1 35 7 3 1 10 350 75 30 10 100 750 300 100 1000 1000 7 10000 10000 70 100000 100000 700 Fig.

Temperature humidity and pressure are controlled as necessary ISO-1 p. The most common ISO clean room classes are ISO 7 and ISO 8. Large numbers like class 100 or class 1000 refer to FED-STD-209E and denote the number of particles of size 05 µm or larger permitted per cubic foot of air.

Up to 4 cash back been laundered in a class 100 cleanroom using ultra-filtered water of 045 micron purity and HEPA-filtered air during moisture removal. US FED STD209E clean room class table overview particles per ft3. The old Federal Standard 209E FS 209E includes these clean room classes.

Class 10000 would have. Recommended Gowning Housekeeping. Class 1000 cleanroom filtration system must provide filter coverage of 20-30 and a minimum of.

Even if its classified as the dirtiest class the ISO 9 clean room environment is cleaner. Even if its classified as the dirtiest class the ISO 9 clean room environment is cleaner than a regular room. Room with a defined concentration of airborne particles designed and used in a way that the number of particles introduced into the room or originating and being deposited in the room is as small as possible and in which other cleanliness-relevant parameters such as temperature humidity and pressure can be controlled as required VDI.

Class 100 area is defined as area where there should not be more than 100 particles of 05 micron per cubic foot of air. Cleanrooms are classified according to the number and size of particles permitted per volume of air. HEPA means high efficiency particulate air.

A class 100 cleanroom to a class 10000 cleanroom refers to this kind of working environment. Separate typically a lesser pressure and less stringent airlock prior to entering the ISO 8 Cleanroom or CNC area. These classifications are assigned based on the maximum allowable concentration of particles per cubic foot or meter of air.

An ISO 6 clean room Class 1000 cleanroom is a soft- or hard-sided wall manufactured structure that utilizes HEPA filtration systems to maintain air cleanliness levels of a maximum of 1000 particles 05 µm per cubic meter of inside air. ISO 1 is the cleanest class of cleanroom while ISO 9 is the least clean. To meet requirements of a clean room as defined by Federal Standard 209E and newer ISO Standards all clean rooms must not exceed a particulate count as specified in the air cleanliness class.

INTRODUCTION ISO 14644-1 definition of a cleanroomA room in which the concentration of airborne particles is controlled and which is constructed and used in a manner to minimize the introduction generation and retention of particles inside the room and in which other relevant parameters eg. The people who work in clean rooms need to wear special suits that prevent them from contaminating the room. A cleanroom or clean room is an engineered space which maintains a very low concentration of airborne particulates.

A Class 100 clean room has no more than 100 particles. Even though ISO 9 cleanroom environments are classified as the least clean theyre still cleaner than a regular room as a standard office space likely contains more than 1 million particles per cubic meter. A laminar flow system provides a homogeneous air speed of 045 ms - 20 at the working position.

Cleanrooms come in different classes from class 100 to 100000. 75 per cubic foot. 30 per cubic foot.

Modern manufacturing processes and scientific research often require specific very clean environmental conditions. The pressure originates on the Class 100 side flows under the curtain to the Class 1000 side and finally travels to the gowning area and outward from there. Meeting Class 100 standards using the low-end air change recommendation 240hour inside a 12 x 12 x 7 3302 mm x 3302 mm x 2134 mm cleanroom with 1008 cu.

This class is frequently used in labs and hospitals because it is designed to never permit over 100 particles 05 microns or bigger per cubic foot of air. Generally speaking a clean room is an enclosed room that has equipment which controls the amount of particulate matter in the air by using air pressure and filters. Cleanrooms start at class 10 and scale up as the air inside.

Class 1000 cleanroom filtration system must provide filter coverage of 20-30 and a minimum of. HEPA means high efficiency particulate air. Class 1000 defined same where there should not be more than 1000 particles and so on respectively.

As an example ISO 8 cleanrooms also known as Class 100000 cleanrooms can be modular or soft-walled. The lower the ISO class the more stringent the requirements for keeping particles and contamination to the acceptable levels of the room class. It is well isolated well-controlled from contamination and actively cleansed.

7 rows A class 100 cleanroom has 100 particles per cubic foot. Contaminants like airborne dust and other particles can cause failure and waste resources. What is a cleanroom.

Grade A this defines the local zone for high-risk operations like filling zone stopper bowls open ampoules and vials and making aseptic connections. Of volume requires 6 FFUs. The Federal Standard 209 FS 209E equivalent for these ISO classes are Class 10000 and Class 100 000.

Class 100 The cleanest room on this list.

We Need To Talk About Greenwashing Lexi S Clean Kitchen Preservative Free Cleaning

100 Most Common Phrasal Verbs List Lessons For English Helping Verbs Verb Examples Verbs List

Pin On Adjectives List In English

Small Floating Dressing Table White Etsy In 2021 Small Dressing Table Wall Dressing Table Dressing Table Design

What Is Iso 8 Cleanroom Classification

Clean Room Classifications Iso Standards Quotes 48 Hours

Clean Room Classifications Iso Standards Quotes 48 Hours

Reverb Cheatsheet Music Mixing Music Engineers Music Tutorials

Pin By Tara Kieser On Clean Eating Edamame Salad Tough Edamame

Programming Variables Tonnage Def Weight Muscle Mass Bodybuilding

Clean Room Classifications Iso Standards Quotes 48 Hours

Facebook Idee Per Diario Organizzazione Delle Idee Planner

Clean Room Classifications Iso Standards Quotes 48 Hours

Clean Room Classifications Iso Standards Quotes 48 Hours

Clean Room Classifications Iso 8 Iso 7 Iso 6 Iso 5 Mecart

Pin Von Joanne Ludlow Auf Crochet Strickmuster Baby Basteln Anleitungen

Clean Room Classifications Iso Standards Quotes 48 Hours

Funny Science Quote Wall Art Research Definition Throw Pillow By Nathan Moore